Old oil tank installation finished manhole well solution

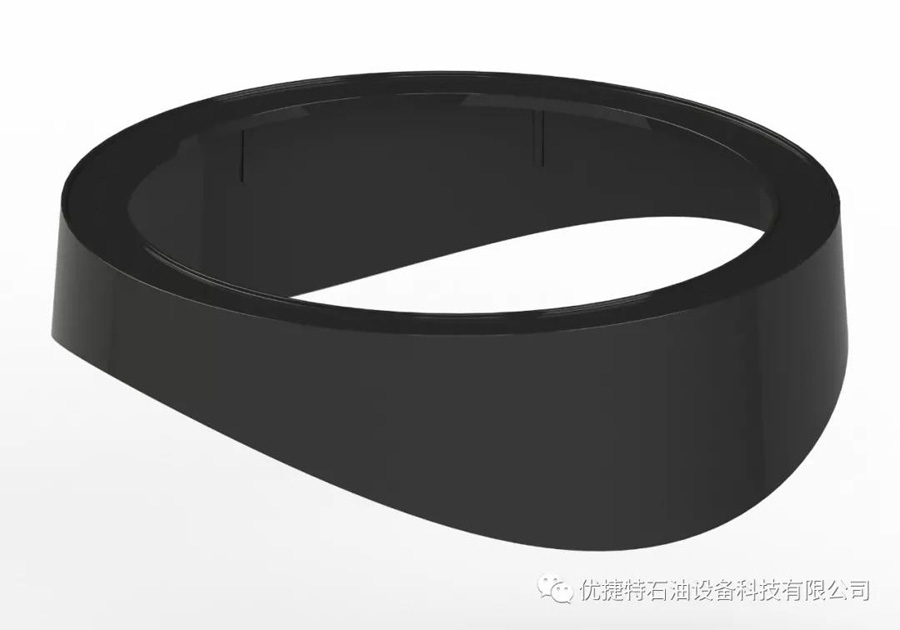

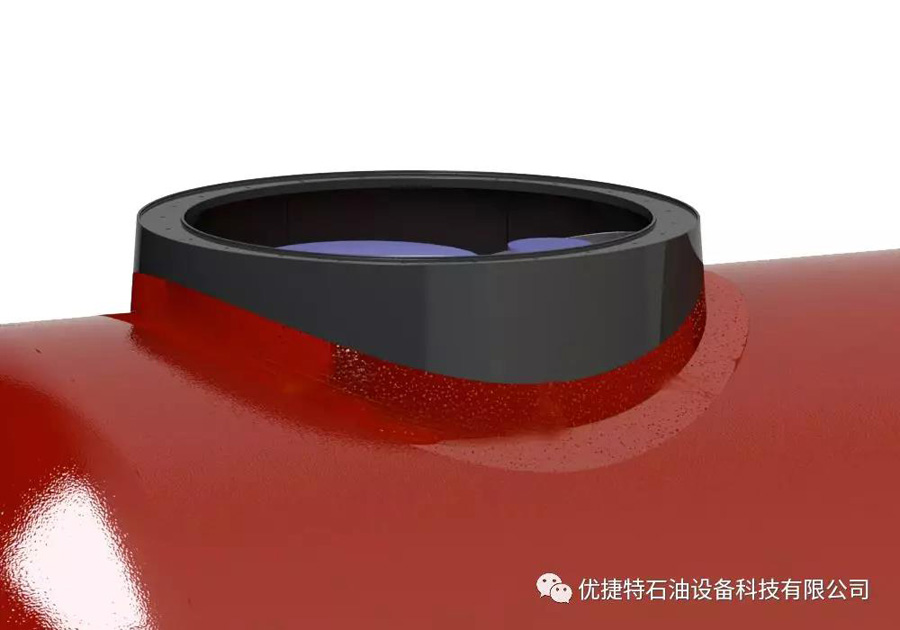

In recent years, during the reconstruction of the gas station, the problem of installing finished manhole Wells in old oil tanks was encountered. The composite manhole well flange developed by Youjet company provides a solution for installing finished manhole Wells in old oil tanks. The product is shown as follows:

Figure 1 composite manhole well flange base

Ⅰ. product features:

Youjiete composite water stop plate flange (Strengthened inward-flanged manhole well (1400)) is made of high strength SMC single-die molding, which has the following advantages:

1. Good size consistency, no deformation and good interchangeability;

2. SMC molding once molding high strength, beautiful appearance;

3. Good product stability, high degree of automation and easy mass production;

4. Good matching with oil tank and easy construction of multiple baselines;

5. Installation operation can be carried out for oil tanks of different diameters.

Ⅱ. Product size:

Overall size: Φ1500X443mm

Net weight: 42kg

Ⅲ. Product installation instructions:

1. Lift the flange of composite water stop plate (hereinafter referred to as flange) to the manhole position of the oil tank, align the marking, remove the flange, and polish 150mm inside and outside the marking area with the grinding wheel of Angle grinder louver, then polish the metal oil tank to produce new metal, and then polish the surface of the glass fiber reinforced plastic oil tank.The following schematic diagram and on-site operation photos:

Figure 2 diagram of grinding area

2. Polish the inner and outer areas of the flange with a height of 100mm into pitted surfaces, and polish all the pitted surfaces in the bonding areas as shown below:

Figure 4 shows the gray and white areas

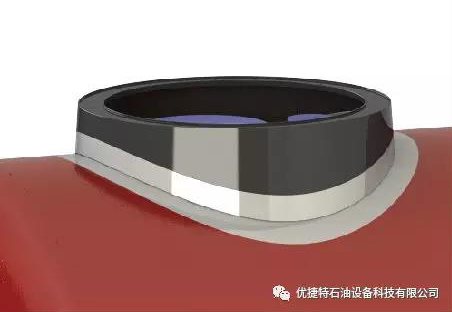

3. Lift the flange onto the oil tank and install the flange with butt datum line and direction arrow aligned with the oil tank axis, as shown below:

Figure 5 installation diagram

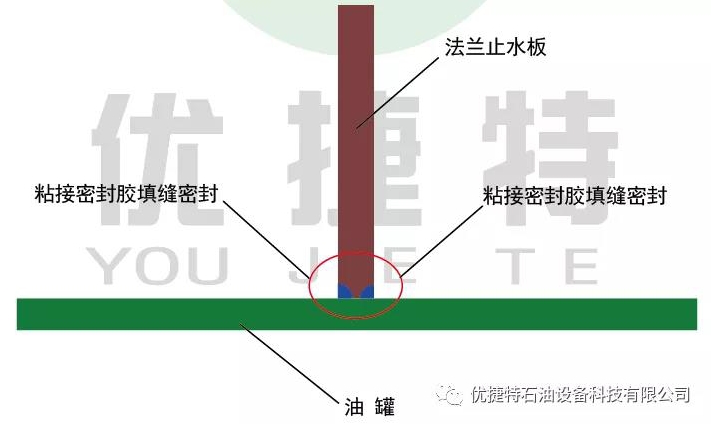

4. Wipe the adhesive area with a clean cloth or blow the dust with an air gun, and seal the seam with adhesive sealant.

Figure 6 caulking diagram

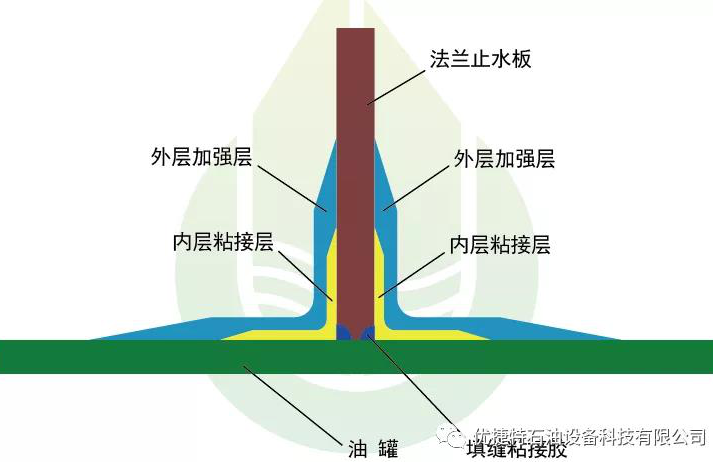

5. When the adhesive sealant is solidified, if the flange is bonded to SF steel wall, special resin for iron bonding and glass fiber felt are needed, and the bonding layer is strengthened with the same resin and glass fiber felt as the outer wall of the oil tank, please see the following figure:

Figure 7 construction bonding diagram

6. After the resin is completely solidified, the flange bonding can be completed. Please see the following figure:

Figure 8 finished effect

Figure 9 site construction drawing

Figure 10 manhole diagram of finished installation

Figure 11 site installation photos

Contact Us

Fax:0086-0318-8625288

Email:

Skype:

Add.:No. 589, Chang’an east road, Jizhou district, Hengshui city, Hebei province,China

English

English 中文

中文

ADD:No. 589, Chang’an east road, Jizhou district, Hengshui city, Hebei province,China

ADD:No. 589, Chang’an east road, Jizhou district, Hengshui city, Hebei province,China

TEL: 0086-0318-8625288

TEL: 0086-0318-8625288

FAX: 0086-0318-8625288

FAX: 0086-0318-8625288

E-MAIL:

E-MAIL: